The Future of Conveyor Belt Cleaning Starts Here

FM8's patented Knife Tips technology and revolutionary tensioner system deliver up to 4x longer blade life and eliminate carryback in the world's harshest mining environments.

While others follow industry standards, FM8 redefines them. Our proprietary tensioner technology represents the first major advancement in primary cleaner design in decades, delivering consistent blade-to-belt pressure that adapts to real-world conditions.

Innovation Focus

Engineered for the harshest mining environments, FM8 scraper blades and tensioners maintain optimal cleaning efficiency from installation to replacement. Less carryback. Less maintenance. More production.

Performance Guarantee

Australian Engineering, Global Standards

Designed and tested in Australia's most demanding bulk material handling operations, FM8 products meet ISO standards while solving the specific challenges of iron ore, coal, and mineral processing applications.

Engineered to Exceed. Patented to Perform.

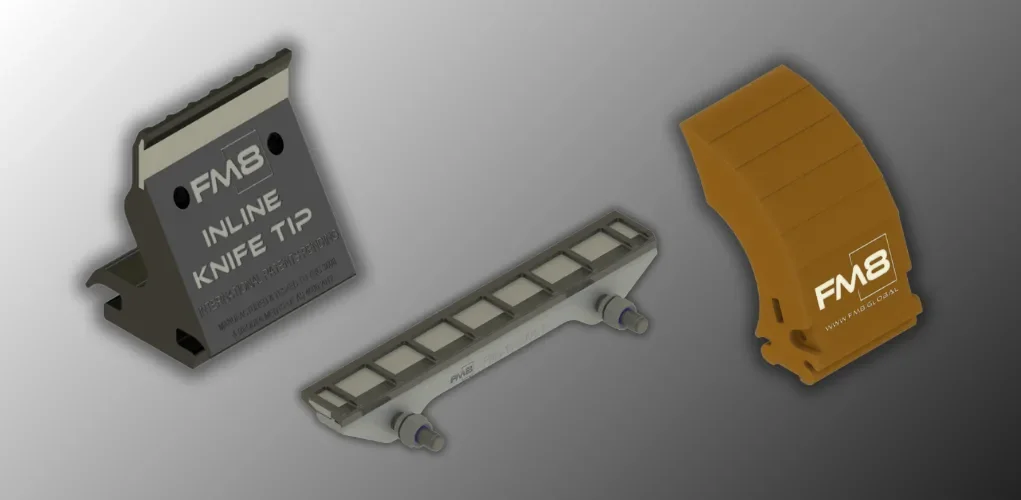

FM8 holds patented technology across two critical conveyor cleaning innovations: our revolutionary Knife Tips scraper blade technology and our game-changing primary cleaner tensioner system. While competitors offer incremental improvements, FM8 delivers breakthrough performance.

STAY UP TO DATE WITH FM8’S LATEST NEWS

Frequently Asked Questions

ABOUT FM8 & OUR TECHNOLOGY

-

FM8 is an innovation-driven engineering company with patented technology across two critical areas: our revolutionary Knife Tips scraper blade system and our game-changing primary cleaner tensioner. While competitors offer incremental improvements to existing designs, FM8 has reimagined how conveyor cleaning works from the ground up. Our solutions are engineered and tested in Australia's harshest mining environments, then protected by international patents to ensure you receive genuine breakthrough performance – not copies or generics.

-

Our Knife Tips technology represents a fundamental redesign of the scraper blade tip. Unlike traditional C-Tip or V-Tip carbide inserts that chip easily and wear inconsistently, our patented knife-edge geometry maintains optimal cleaning angle throughout the entire wear life. The modular quick-change system reduces blade replacement time by up to 70%, while our proprietary carbide formulation delivers up to 4x longer life than standard tungsten carbide tips. Most importantly, Knife Tips are safe for both vulcanised and mechanically-spliced belts – unlike many traditional carbide designs.

-

Traditional tensioners – whether spring-loaded, air-powered, or manual – struggle to maintain consistent blade-to-belt pressure as blades wear or belt conditions change. Our patent-pending tensioner system uses (adaptive/self-adjusting - adjust based on actual mechanism) technology that automatically maintains optimal cleaning pressure regardless of blade wear, belt sag, or material load. This eliminates the "set it and forget it" failure mode where cleaners lose effectiveness over time, and the "over-tensioning" problem that damages belts and blades prematurely.

-

While FM8 technology was developed and proven in extreme mining environments – iron ore, coal, copper, gold, and mineral sands – our solutions are ideal for any bulk material handling operation experiencing carryback, spillage, or excessive maintenance. This includes quarry and aggregate operations, cement production, port and terminal facilities, power generation, and recycling operations. If you have a conveyor belt, FM8 can improve its performance.

-

FM8 systems are designed for straightforward installation by qualified conveyor maintenance personnel. Our primary cleaner installs using standard mounting brackets and requires no special tools. The revolutionary aspect is our Knife Tips replacement system – individual tips can be changed in 10-15 minutes using simple hand tools, compared to 30-45 minutes for traditional blade cartridges. This means maintenance can be performed during routine shutdowns rather than requiring dedicated cleaning system outages.

-

Unlike spring tensioners that require regular adjustment or air tensioners that need compressor maintenance, our patent-pending tensioner is designed to be virtually maintenance-free. The self-adjusting mechanism continuously optimizes blade pressure without operator intervention. We recommend visual inspection during routine conveyor maintenance, but no regular adjustment, lubrication, or calibration is required. This "fit and forget" reliability is one of the most valued benefits reported by FM8 customers.

-

FM8 Knife Tips feature visible wear indicators that make inspection simple. Unlike traditional blades where wear is gradual and hard to detect, our tips show clear colour-change or geometry markers when replacement is needed. Additionally, because our tensioner maintains constant pressure, you'll notice consistent cleaning performance right up until replacement is required – no gradual degradation or increasing carryback. Most customers establish preventive replacement schedules based on tonnage throughput rather than waiting for performance decline.

INSTALLATION & MAINTENANCE

Product Performance & Technical

-

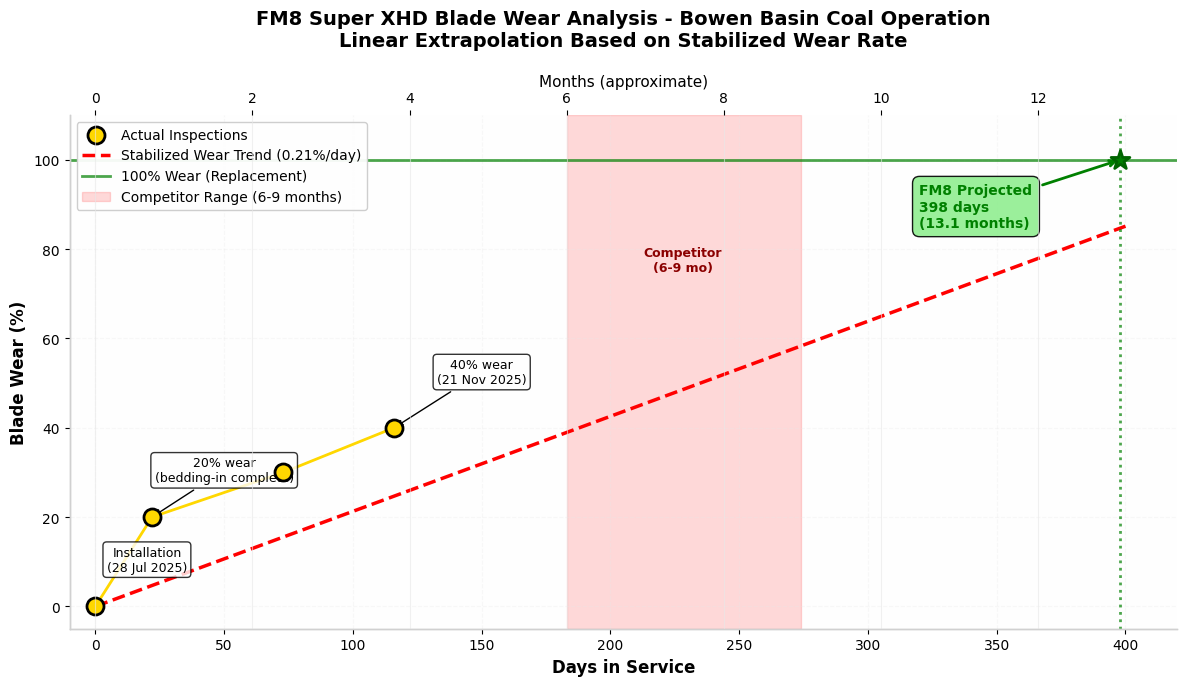

In head-to-head field trials against premium tungsten carbide tips, FM8 Knife Tips consistently deliver 3-4x longer wear life in high-abrasion applications like iron ore and copper mining. The patented geometry maintains consistent cleaning pressure throughout the wear cycle, unlike traditional tips that degrade rapidly once the edge rounds. Actual life depends on material abrasiveness, belt speed, and loading conditions, but our customers typically report 6-12 months between tip replacements compared to 2-3 months for conventional carbide tips.

-

No. Unlike early carbide tip designs that could catch and damage mechanical fasteners, FM8 Knife Tips feature a patented retention and geometry system that is safe for all belt splice types – including vulcanised, mechanical (clipper, alligator, rivet), and staple-style fasteners. This was a key design criterion from the outset, ensuring you get premium cleaning performance without risking expensive belt damage or splice failure.

-

FM8 primary cleaners and Knife Tips are designed for standard belt widths from 450mm to 2400mm (18" to 96"), with custom solutions available for specialised applications. Our systems accommodate belt speeds up to 5 m/s (1,000 fpm) in standard configuration, with high-speed variants available for faster operations. Contact our engineering team for specifications outside these ranges.

-

In many cases, yes. FM8 offers adapter systems that allow our Knife Tips to be installed on most major primary cleaner brands. However, for optimal performance, we recommend our complete FM8 primary cleaner system with integrated tensioner technology. The combination of patented Knife Tips and our adaptive tensioner delivers performance that retrofits alone cannot match. Our site assessment team can evaluate your existing equipment and recommend the best approach.

INDUSTRY & APPLICATIONS

-

Carryback is an environmental and safety hazard – spillage creates housekeeping hazards, dust emissions affect air quality, and material loss represents wasted resources. FM8's superior cleaning efficiency eliminates up to 99% of carryback, dramatically reducing these risks. Our customers report improved workplace safety scores, reduced cleanup labor, and better environmental compliance. Additionally, our longer-lasting Knife Tips reduce waste from frequent blade replacements.

-

While specific ROI depends on your operation, FM8 customers typically see payback within 3-6 months through reduced carryback cleanup labor, extended blade life (3-4x longer), reduced belt wear from over-tensioning, and eliminated unplanned shutdowns for cleaner maintenance. One Pilbara iron ore operation reported annual savings of 180,000 after switching to FM8 systems – calculated from labor reduction alone, not including improved production uptime. We provide ROI calculators and can project savings specific to your operation during our site assessment.

-

Absolutely. FM8 technology excels in challenging applications where traditional cleaners fail. Our Knife Tips maintain cleaning performance in wet coal, sticky bauxite, or clay-rich iron ore that would clog or glaze conventional blades. The constant pressure from our tensioner system ensures the blade maintains contact even when material adheres to the belt surface. We have specific formulations and configurations for high-moisture or cohesive materials – ask about our specialty applications.