FM8 Super XHD Blades Deliver 45-118% Lifespan Improvement at Bowen Basin Coal Operation

Australian polyurethane cleaning blade technology outperforms competitor blades in demanding washed coal application.

July 2025 – Bowen Basin, Queensland, Australia

When a major mining operation in Queensland's Bowen Basin sought to improve their conveyor belt cleaning efficiency, they turned to FM8's Super XHD Standard Duty Yellow polyurethane primary blades. Six months into the installation, the results are exceeding all expectations—and redefining what's possible for blade longevity in high-speed coal handling.

The Challenge: High-Speed Washed Coal Handling

Operating in one of Australia's most demanding coal regions, this site runs conveyor belts at speeds up to 6 m/s handling washed coal—a notoriously abrasive material that punishes wear components. Previously, the operation relied on competitor polyurethane blades that typically required replacement every 6 to 9 months, creating maintenance bottlenecks and increasing operational costs.

The goal was simple: find a blade that could not only survive the harsh Bowen Basin conditions but deliver measurable value through extended service life and consistent cleaning performance.

The FM8 Solution: Super XHD Standard Duty Yellow

Installed on July 2025, the FM8 Super XHD blades feature a design optimised for high-speed applications. The distinctive yellow formulation represents FM8's advanced polyurethane compound, engineered specifically for the unique challenges of Australian coal handling.

Figure 1: FM8 Super XHD blades at installation (July 2025) – pristine condition ready for high-speed service

Performance Data: Exceeding Expectations

Regular inspections tracked blade wear progression over four months:

|

Date |

Days in Service |

Wear % |

Notes |

|---|---|---|---|

|

July 2025 |

0 | 0% |

Installation |

|

August 2025 |

22 | 20% |

Initial bedding-in complete |

|

October 2025 |

73 | 30% |

Stabilised wear rate established |

|

November 2025 |

116 | 40% |

Continued strong performance |

Figure 2: Inspection on 9 October 2025 – 30% wear with uniform segment degradation and intact cleaning efficiency

Wear Analysis & Life Projection

Engineering analysis of the wear data reveals exceptional performance:

Key Findings:

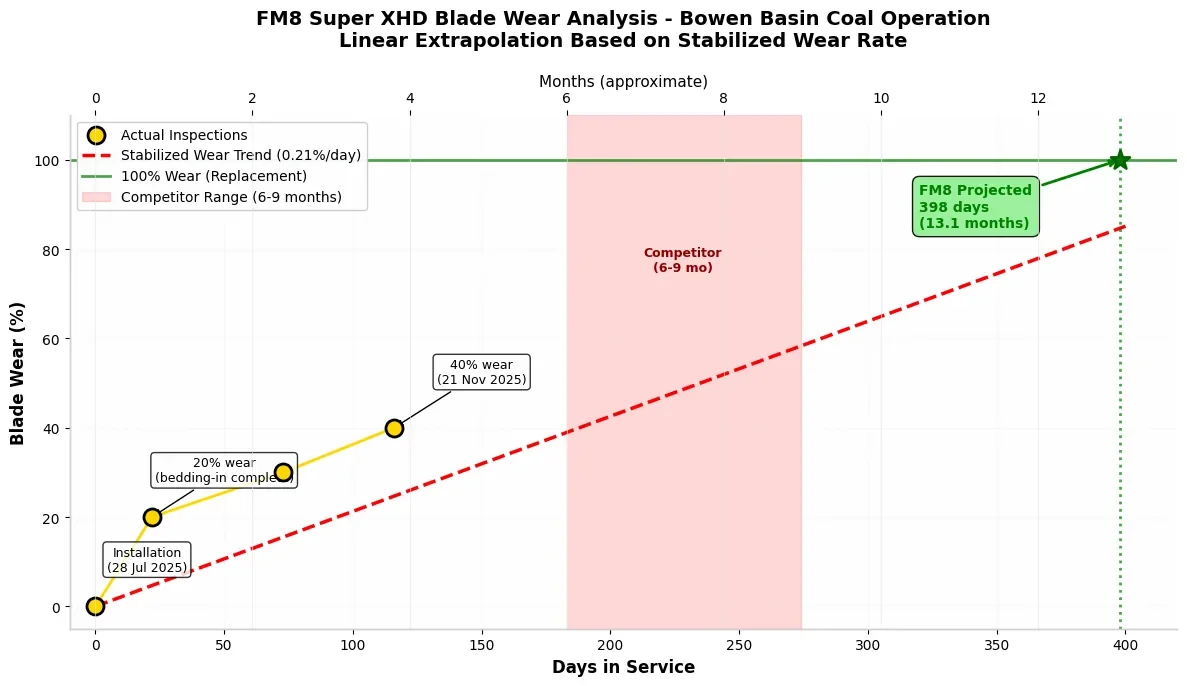

Bedding-in period: Initial 20% wear occurred over first 22 days (0.91%/day)

Stabilized wear rate: Subsequent wear slowed to 0.21% per day (6.5% per month)

Current status: 40% wear at 116 days (~4 months)

Projected Lifespan: Based on the stabilised wear rate observed from August through November, linear extrapolation indicates:

Total projected service life: 398 days (13.1 months) Projected replacement date: August 2026

This represents a 45% improvement over the competitor's best-case 9-month lifespan, and a remarkable 118% improvement over the 6-month average previously experienced.

Figure 3: 21 November 2025 inspection – 40% wear with predictable degradation pattern indicating substantial remaining service life

Value-Add Analysis: The FM8 Advantage

1. Extended Maintenance Intervals By projecting to 13+ months versus 6-9 months, FM8 Super XHD blades reduce change-out frequency by 50-118%. In a 24/7 operation, this translates to:

Reduced maintenance labour costs

Fewer production interruptions

Lower safety exposure hours

2. Consistent Cleaning Efficiency FM8’s design maintains optimal blade-to-belt contact throughout the wear life. Unlike competitor blades that often suffer from uneven wear or profile distortion, the FM8 design shows uniform blade wear—ensuring consistent carryback control from day one to replacement day.

3. Superior Polyurethane Formulation The "Standard Duty Yellow" compound demonstrates exceptional abrasion resistance in washed coal service. The stabilized wear rate of just 6.5% per month (after bedding-in) indicates superior material density and tear strength compared to standard market offerings.

4. High-Speed Compatibility Operating successfully at 6 m/s belt speed validates the blade's mechanical design and material stability under dynamic loading—critical for modern high-capacity coal handling systems.

Customer Impact

"The FM8 blades have exceeded our expectations. We're seeing wear characteristics that suggest we'll get well over 12 months of service—nearly double what we were achieving previously. The consistent cleaning performance has also reduced our carryback issues significantly."

— Maintenance Team, Bowen Basin Operation

Technical Validation

The wear progression follows established polyurethane behaviour: an initial higher wear rate during surface bedding-in (first 20%), followed by a stable, predictable wear pattern. This "two-phase" wear curve is characteristic of high-quality polyurethane formulations where the material achieves optimal surface hardening after initial service.

The R² correlation of 0.89 for linear regression across all data points indicates highly predictable wear behaviour—essential for maintenance planning and inventory management.

Conclusion

For operations in the Bowen Basin and similar high-abrasion coal environments, FM8 Super XHD blades deliver quantifiable value:

|

Metric |

Competitor |

FM8 Super XHD |

Improvement |

|---|---|---|---|

|

Average Lifespan |

6-9 months | 13.1 months (projected) |

+45-118% |

|

Wear Rate (Stable) |

Variable | 6.5%/month |

Predictable |

|

High-Speed Rating |

Limited | 6 m/s+ |

Proven |