business case

FM8 Primary XHD Blades- Field Trial

Executive Summary

Proven Superiority of FM8 Primary XHD Conveyor Blades:

A Data-Driven Case from an Australian mine site

A recent field trial at a demanding mine site provides conclusive evidence that standardising on FM8 primary XHD conveyor blades is a superior business decision. While the FM8 blade has a slightly higher purchase price, its 50% longer service life—proven in real-world conditions—fundamentally transforms its value proposition.

For a standard operation with at least 5 conveyors, this translates to:

Direct Annual Cost Savings: $13,532 in reduced blade purchases and labour.

Major Risk Reduction: 11 fewer high-risk maintenance events per year, slashing exposure to manual handling injuries and machinery interactions by 33%.

Operational Efficiency: Freedom from 11 change outs liberates valuable supervisory hours and increases plant availability.

The trial data moves the debate beyond invoice price to Total Cost of Ownership. The FM8 primary XHD blade is not an expense; it is a strategic investment in safety, operational stability, and profitability. We recommend the immediate standardisation of FM8 primary XHD blades across all sites.

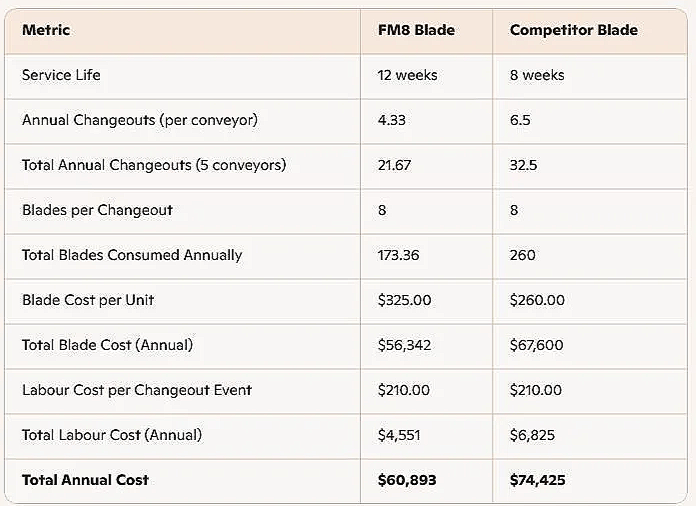

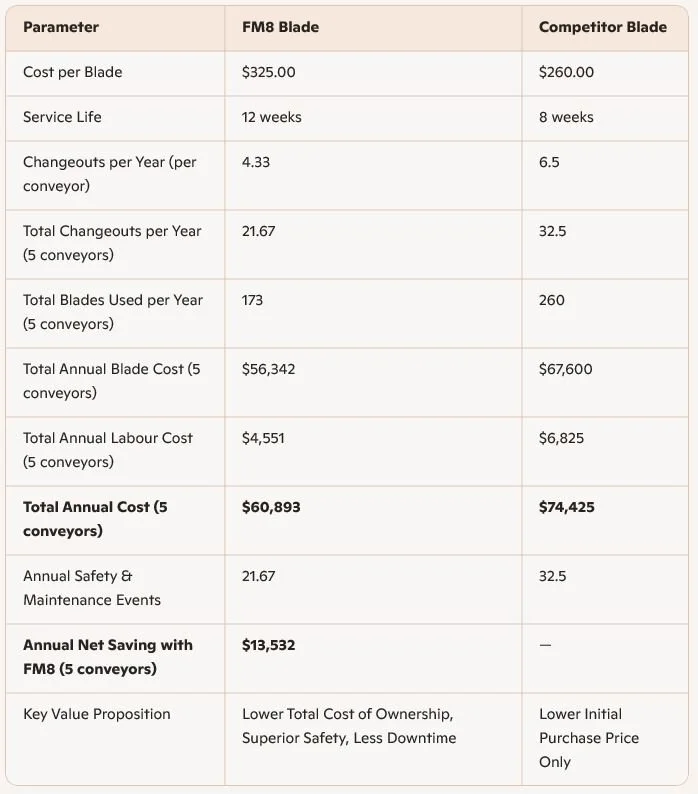

1. Field Trial Parameters & Financial Baseline

The trial was conducted under typical running mine conditions, providing a realistic benchmark for performance and cost.

2. Financial Analysis for a 5-Conveyor System

Annual Net Saving with FM8 Blades:

$74,425 (Competitor) - $60,893 (FM8) = $13,532

The site trial data, with its higher blade costs, reveals even greater absolute savings.

3. Mine Context: Safety & Risk Analysis

The financial savings are compelling, but in a high-risk environment, the safety and risk mitigation benefits are equally critical.

3.1. Demonstrated Risk Reduction

The trial proved that using FM8 blades leads to 10.83 fewer change out events per year for a 5-conveyor system. This directly reduces exposure to critical risks:

Manual Handling Injuries: Each event involves lifting heavy blades and tools. A 33% reduction in events is a 33% reduction in exposure to musculoskeletal disorders, a common LTIFR contributor.

Contact with Machinery: Fewer LOTO (Lockout-Tagout) procedures and interactions with conveyor structures lower the risk of crush injuries, entanglement, and fatalities.

Site Vehicle Movement: Fewer contractor visits mean less light vehicle movement in the plant, reducing interaction with heavy equipment.

3.2. Contractor Management & Productivity

The Australian mining industry faces significant challenges with contractor management and labour costs.

Reduced Supervisor Burden:

Each change out requires a Permit to Work, JSA review, and supervision. 10.83 fewer events free up hundreds of hours of supervisor time annually, allowing them to focus on more critical tasks.

Lower Intrinsic Risk: Every contractor on site represents a risk. Reducing the contractor footprint by a third directly lowers the site's overall Total Recordable Injury Frequency (TRIFR) exposure.

Increased Plant Availability:

Fewer planned shutdowns for maintenance mean more available hours for production, a key metric for any mining operation.

4. Total Value Assessment: Beyond the Invoice Price

The field trial moves the discussion from theoretical cost to proven total value.